I-Beam Cable Trolley

Our cable trolleys are engineered for efficient and reliable cable management in cranes, hoists, and material handling systems. Designed with heavy-duty steel and corrosion-resistant materials, each heavy duty cable trolley and cable carrier trolley ensures smooth movement of cables while minimizing wear and tear.

We provide a wide range of solutions, including I beam cable trolly, double decor I beam trolley, festoon cable trolley, festoon trolley, and overhead crane cable trolley—all tailored for industrial use. Our specialized options such as crane cable carrier trolley, EOT crane cable carrier, cable trolley for EOT crane, and EOT crane cable trolley deliver durability, safety, and superior performance.

Easy to install and maintain, these trolleys are suitable for both C-Rail and I-Beam festoon systems. With robust construction and long service life, our cable trolleys are the trusted choice for safe, smooth, and reliable cable handling in demanding industrial applications.

Description

Common Uses

CT-22

multi cable Nickel Plating

CT-23

25mm to 38mm

CT-24

16mm to 20mm

CT-25

Alliminium Wheel 25mm to 38mm

CT-26

multi cable Flat cable

CT-27

multi cable Flat cable

CT-28

Tow wheel multi cable

CT-29

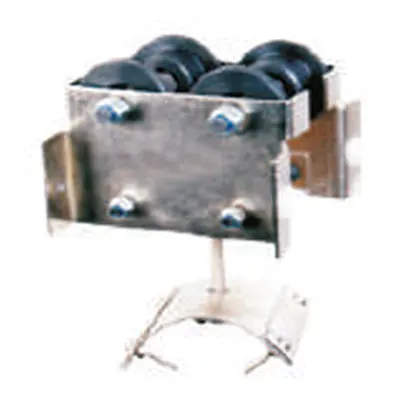

Four wheel multi cable

CT-30

Four wheel (adjustable) multi cable

CT-31

Four wheel (Round-Flat Cable) 38mm to 75mm

CT-32

Heavy wheel (Adjustable) multi cable

CT-32

UnbreakablePlastic Four Wheel Heavy Trolley, Multi Cable/Flat Cable

CC-01

Cable Clamping Dia : 7 to 14 mm

CC-01 new

Cable Clamping Dia : 7 to 14 mm

CC-02

Cable Clamping Dia : 16 to 20 mm

CC-03

Cable Clamping Dia Single Cable Flat 16 to 35 mm

CC-04

Cable Clamping Dia Tow Cable Flat 16 to 35 mm

CC-05

Cable Clamping Dia 25mm with bush type

CC-06

Cable Clamping Dia 38mm with bush type

CC-07

Cable Clamping Dia : 11 to 25 mm

CC-08

Cable Clamping Dia : 7 to 14 mm

CC-09

Cable Clamping Dia : 16 to 20 mm

CC-09 new

Cable Clamping Dia : 16 to 20 mm

CC-10

Cable Clamping Dia Single Cable Flat 16 to 35 mm

CC-11

Cable Clamping Dia Tow Cable Flat 16 to 35 mm

CC-12

Cable Clamping Dia : 25 mm

CC-13

Cable Clamping Dia : 11 to 38 mm

CC-14

Cable Clamping Dia : 11 to 38 mm

Metal Cable

Carrier

Fill the contact Form and we will contact you shortly.

FAQs – Cable Trolleys for Cranes and Hoists

A cable trolley is a device that guides and supports power and control cables in cranes, hoists, and material handling systems. It ensures smooth cable movement, reduces wear and tear, and prevents electrical hazards, enhancing safety and operational efficiency.

We provide a comprehensive range, including:

- I beam cable trolley

- Double decor I beam trolley

- Festoon cable trolley & festoon trolley

- Overhead crane cable trolley

- Specialized options like crane cable carrier trolley, EOT crane cable carrier, cable trolley for EOT crane

Yes. Our trolleys are made of heavy-duty steel and corrosion-resistant materials, designed to withstand harsh industrial environments while providing reliable, long-lasting performance.

Absolutely. Our cable trolleys are compatible with C-Rail and I-Beam festoon systems, making them versatile for various crane and hoist configurations.

- Smooth and reliable cable movement

- Reduced cable wear and maintenance

- Enhanced safety and operational efficiency

- Long service life and durability

- Easy installation and low maintenance

An EOT crane cable trolley is specifically designed for electric overhead traveling cranes, ensuring precise cable guidance, smooth motion, and compatibility with high-capacity crane systems.

Yes. They are designed for quick installation, minimal maintenance, and reliable operation, even in demanding industrial settings.

Yes. We offer customized cable trolley solutions based on crane type, cable size, load requirements, and operational environment.

Our cable trolleys are widely used in steel plants, ports, warehouses, construction sites, manufacturing facilities, and material handling industries.

By ensuring organized, stable, and smooth cable movement, cable trolleys reduce the risk of cable entanglement, electrical hazards, and operational downtime, enhancing overall crane safety and efficiency.